Click here for details

Fouling on RECON Sensors

Factory Anti-Fouling Measures

Fouling can be defined as the accumulation of biological organisms, such as bacteria, algae, and barnacles. If left unchecked, it can inhibit the normal operation of the sensors and consequently can lead to noisy data or incorrect concentrations.

Factory-Equipped Anti-Fouling Measures

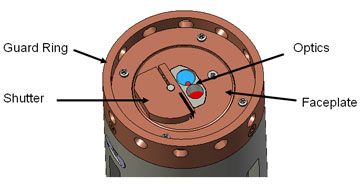

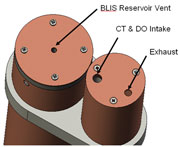

The sensors come equipped with a variety of anti-fouling features. Copper is naturally resistant to fouling. The fluorometers uses a copper face plate and a copper shutter that covers the optics when the fluorometer is not sampling, preventing the sensors from becoming fouled by the growth of algae and other marine organisms. When a sample is about to be taken, the shutter opens. During this process, a wiper blade on the shutter removes anything that has settled on the optical ports. After sampling, the shutter closes. Copper-cladding is also used to protect the inlet and outlet of the CT-DO chamber and the vent for the Bleach Injection System (BLIS) reservoir.

In addition to copper cladding, the WQM employs a couple of chemical defenses to combat fouling. The CT-DO chamber is protected by a TBT (Tributyltin) impregnated 'doughnut' located at the inlet and outlet of the cell to prevent bacteria from colonizing on the DO membrane. Additionally, the bleach injection system (or BLIS) injects a minute amount of bleach (several µL per pump cycle) into the flow cell after a sample is taken to minimize the formation of bacterial biofilms. The flow cell also protects the ISUS probe tip as well.

SCCF Modifications

Prior to deployment each RECON sensor must be disassembled and extensive anti-fouling measures implemented (at SCCF). Each component is wrapped with a plastic tape. This allows the non-toxic anti-fouling paint to be applied and to be easily removed by simply pulling off the tape for monthly or annual servicing. This is especially time-saving when returning the sensors to the manufacture for annual servicing and recalibration.

All holes in the mounting cage struts are capped with plastic. Several coats of an anti-fouling paint are then applied to the tapped components and the mounting cage.

Interconnecting cables are also wrapped with a copper foil tape to reduce fouling. Several days are required to complete the anti-fouling measures requiring the complete disassembly of the sensor package (see below).

Note that this treatment only helps to minimize fouling not prevent it. Periodic maintenance (scrubbing by divers) is needed to prevent significant fouling from affecting the sensors (see below image.)